Welcome to Guilin HCM Machinery Official WebSite!

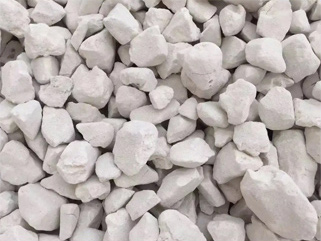

Composition requirements:

CaO3 content>85%

Particle size requirements:

180 mesh (building materials industry)

200-325 mesh (desulfurizer, sewage treatment, decolorizer, etc.)

Industrial grade calcium hydroxide

Composition requirements: Ca(OH)₂ content>90%

Particle size requirement: 200-325 mesh

Other requirements: moisture <1%

Calcium ash powder (building materials industry)

Composition requirements: Ca,Mg,Si>90%

Particle size requirement: 325-600 mesh

Other requirements: moisture <2%,whiteness>90%

Calcination: The selected limestone is sent to the environmental protection lime kiln for high-temperature calcination to become quicklime.

Grinding: quicklime can be directly crushed by Raymond mill or vertical mill, and processed from block ash to powder ash.

Digestion: quicklime can also be further processed, sent to the calcium hydroxide production line, and turned into mature lime.

Powder classification+collection: the slaked hydrated lime can be screened directly through the powder concentrator. After collection, it will be the refined calcium hydroxide product.

Guilin Hongcheng professional team provides a one-stop production plan for the lime deep process. According to the specific project needs, we will provide you with one-on-one professional guidance and technical exchange. Provide efficient and timely services from pre-sale, in-sale to after-sale to make the lime deep processing project more smooth and effective.